MultiMAMSS - Multi-Material Additive Manufacturing

MultiMAMSS - Multi-Material Additive Manufacturing

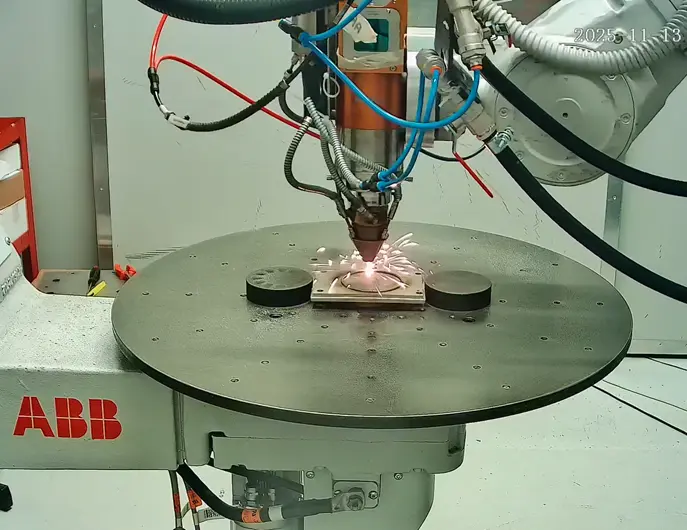

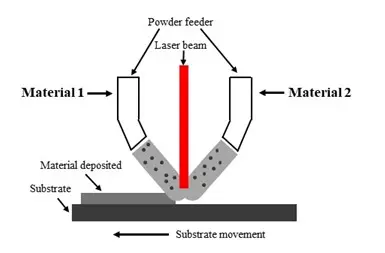

Multi-Material Additive Manufacturing of S690/Fe-Mn-Si-Cr-Ni SMA Joints with 30% Enhanced Static and Fatigue Life for Structural Applications through L-DED

Saad Waqar (MSCA Fellow), Alper Kanyilmaz (Supervisor), Ali Gokhan Demir (Co-Supervisor)

The European Union (EU) is the world’s second-largest steel-producing region, with an annual output of approximately 150 million tons. Given that steel production is a major contributor to waste generation and CO₂ emissions, innovative and sustainable manufacturing strategies are urgently required. This project introduces multi-material (MM) steel structural components fabricated via a resource-efficient Laser Directed Energy Deposition (L-DED) process. The proposed approach aims to overcome the conventional trade-off between strength and ductility in steel structures, targeting a minimum 30% enhancement in fatigue life. The resource-efficient L-DED process will enable the production of steel components with minimal material waste and seamless integration of dissimilar alloys, which are otherwise challenging to achieve using traditional methods. The developed multi-material structures are expected to demonstrate at least a 30% improvement in overall life-cycle performance, thereby significantly reducing waste across steel-intensive industries. Initially, a high-fidelity digital frameworkwith >90% predictive accuracywill be established to simulate, analyse, and optimize the L-DED process, thereby minimizing the need for experimental trials. Subsequently, the process parameters and interface strengthening strategies will be optimized to fabricate defect-free, high-density components (>99% relative density). Finally, experimental validation will confirm a 30% increase in service life of the proposed S690/Fe–Mn–Si–Cr–Nimulti-material structural joints under extreme static, dynamic, and thermal loading conditions.

The project outcomes will establish a scientific and technological foundation for developing multi-material steel components with tuneable mechanical performance, while positioning the L-DED process as a viable and sustainable route for advanced structural manufacturing in the EU and beyond.

Contribution to SDG: 9, 12, 13

DABC activities

DABC is the coordinator of the project, involved in all activities - from management to active research.

Partner

Department of Mechanical Engineering, Politecnico di Milano, & Cimolai SpA